Metal Injection Molding (MIM) Market Analysis By End-Use (Automotive, Consumer Product, Medical, Industrial, Defense), By Region (North America, Europe, Asia Pacific, CSA, MEA),Competitive Landscape, And Segment Forecasts, 2014 – 2025

Industry Insights

The global metal injection molding (MIM) market size was valued at USD 2.1 billion in 2015 and is projected to grow at a CAGR of 11.9% from 2016 to 2025. Rapid growth experienced by this industry attributes to increasing demand from end-use industries such as automotive & aerospace, consumer goods, and medical devices.

Metal parts produced from MIM technology are utilized across industries owing to faster processing time, elimination of secondary operations, and better tolerance levels offinal products. Exponential technological progress has fostered the development of a wide array of components that can be manufactured easily with differing sizes and high complexities using injection molding process.

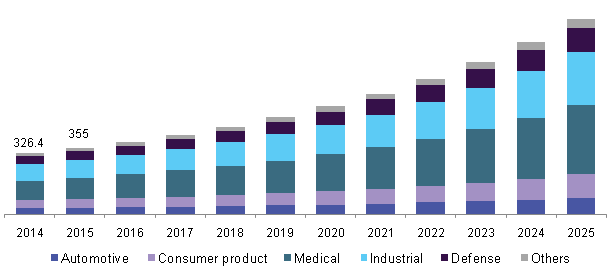

U.S. metal injection molding market by end-use, 2014 – 2025 (USD Million)

Manufacturers prefer the metal injection molding process on account of minimum finishing operations, reduced material wastage, and production of unlimited components with enhanced properties. MIM is a relatively more cost effective technology as compared to other conventional fabrication methods since it lowers raw material usage, workforce, and inventory costs.

Products manufactured using this process also tend to display better mechanical properties that are superior to other powder metal (PM) parts & castings. These products also reflect high sintered density and fine particle size that expects to benefit manufacturers that require components with exceptional mechanical properties.

End-use Insights

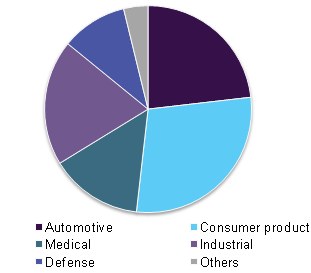

The metal injection molding market has diversified into distinct applications, of which the consumer products and automotive segment have shown tremendous advancements. The large demand for smartphones & other electronic products is likely to support growth since several components such as lightning connectors, phone flip slider & fiber-optic parts are produced using MIM machines.

The increasing usage of high strength components in engines & electronic systems is likely to prove conducive to future growth in the automobile industry. Powdered alloys manufactured from this process significantly enhance engine performance & reduce vehicular fuel consumption. Increasing demand for lightweight & smaller automotive parts is also generating lucrative opportunities for MIM technology.

Injection molding technique used in the manufacture of orthodontic brackets, drug delivery devices, joint replacement equipment, and various implant parts are contributing significantly to the medical device industry. High-volume production of complex three-dimensional shapes is a major growth driver as well.

Rapid industrialization in the Asia Pacific is expected to boost the demand for tools, small components, metal parts, used in the industrial sector. Firearm manufacturers are utilizing this technology to produce different components such as slide stops, magazine catches, spears, floorplates, bolt sleeves, rifle trigger guards, safety levers, and telescopic table bases.

The U.S. firearm market has seen rapid expansion in recent years owing to increased defense budget and government spending on ammunition acquisition. These factors are expected to drive investments in the industry, particularly for firearm applications.

MIM market share by end-use, 2015

Regional Insights

Asia Pacific dominates the industry owing to rapid industrialization, technological advancements, high GDP growth rates, and increasing demand from automotive, consumer durables, and machining sector. Asia Pacific is expected to register the highest growth over the forecast period.

North America emerged as the second major consumer and is expected to grow at a CAGR of 10% in the forth coming years. The U.S. & Canadian governments are providing numerous tax benefits to support the initiative of reduced carbon footprint which has increased preference for Metal injection molding technique.

Competitive Insights

Report Scope

| Attribute | Details |

| Base year for estimation | 2015 |

| Actual estimates/Historic data | 2014 & 2015 |

| Forecast period | 2016 – 2025 |

| Market representation | Revenue in USD Million & CAGR from 2016 to 2025 |

| Regional scope | North America, Europe, Asia Pacific, Central & South America & MEA |

| Country scope | U.S., Canada, Mexico, UK, Germany, France, Japan, China, India, Brazil, South Africa |

| Report coverage | Revenue forecast, competitive landscape, growth factors and trends |

| 15% free customization scope(equivalent to 5 analyst working days) | If you need specific market information, which is not currently within the scope of the report, we will provide it to you as a part of customization |

Segments covered in the report

This report forecasts revenue growth and provides an analysis on the latest trends in each of the sub-segments from 2014 to 2025. For the purpose of this report, Grand View Research has segmented the global MIM market on the basis of end-useand region:

- End-Use Outlook (Revenue, USD Million, 2014 – 2025)

- Automotive

- Consumer Product

- Medical

- Industrial

- Defense

- Others

- Regional Outlook (Revenue, USD Million, 2014 – 2025)

- North America

- U.S

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Asia Pacific

- China

- India

- Japan

- Middle East and Africa

- South Africa

- Central & South America

- Brazil

- North America